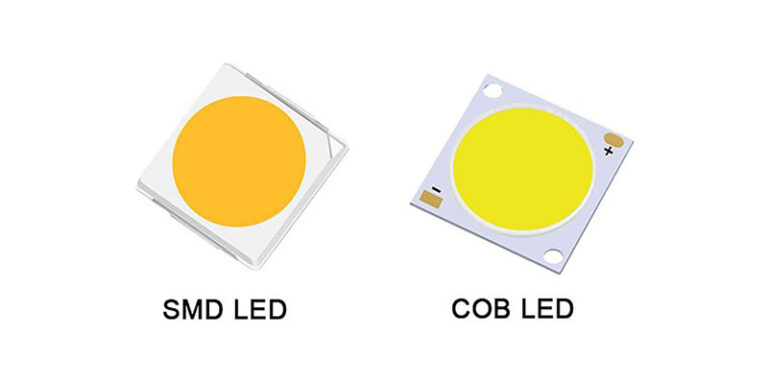

What Is The Difference Between SMD And COB LED lights

#1 Brief development of LED for illumination Generally Speaking, LED stands for Light-Emitting Diode. 1.1 DIP The first LED designed for illumination was the dual

#1 Brief development of LED for illumination Generally Speaking, LED stands for Light-Emitting Diode. 1.1 DIP The first LED designed for illumination was the dual

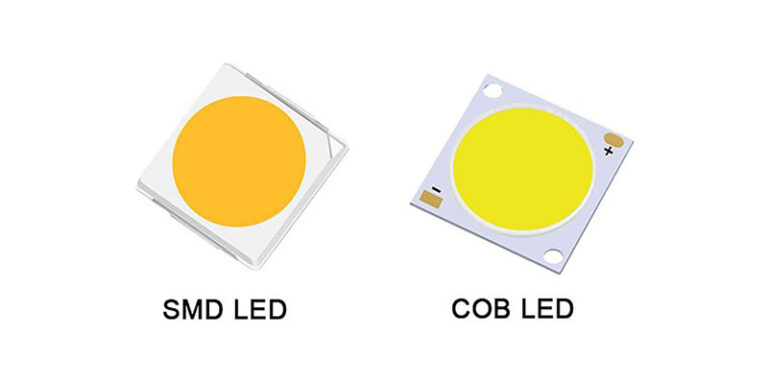

The IESNA (Illuminating Engineering Society of North America) has defined various light distribution types. Light fixtures are designed to fall under one of the types

Are you looking for a solar-energy-based illuminating solution for either your own courtyards or some public sites, such as playgrounds, pathways, parking lots, plazas, etc?

It has been known that south-facing solar panel (In the Northern Hemisphere) can get the most out of sunshine. And when it comes to orienting

Every day, a better and improved solar technology is being researched to effectively harness the sun’s energy. The current solar technologies aren’t as efficient as

Why should I invest in solar energy? What is in it for me? Is solar energy a perfect option? What about its faults? These questions

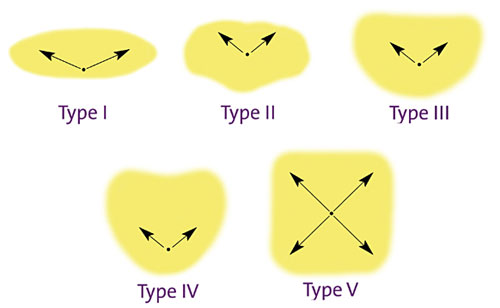

In the course of designing an off-grid solar street lighting system, you’re often faced with an initial challenge of factoring the Peak Sun Hours of

In the course of designing solar led street lights, just like many, you’d often encounter the problem of accurately sizing the battery. This is because,

A solar power system(solar street lighting) is a reliable solution to harness and use energy obtained from the sun. And a solar battery is an

With the development of photovoltaic technology, the conversion efficiency of solar panels has improved significantly: from 5% in 1945 (the solar panel’s inception) to 20%

WhatsApp us

Send us your requirements, we will get back to you within 12 hours